Super Strong Super Bainite

Interview with

Ben - Steel is an enormously versatile metal and centuries of trial-and-error bucket chemistry has given us a wide range of steel alloys that are capable of performing every task that we set. So it might surprise you to hear that steel can still surprise us with previously unthought of properties. Here to tell us more about a new variety of steel, super-strong super bainite, is Professor Harry Bhadeshia who invented super bainite at Cambridge University. Harry, thank you ever so much for joining us.

Harry - It's my pleasure.

Ben - So, tell us what's so special about this new type of steel?

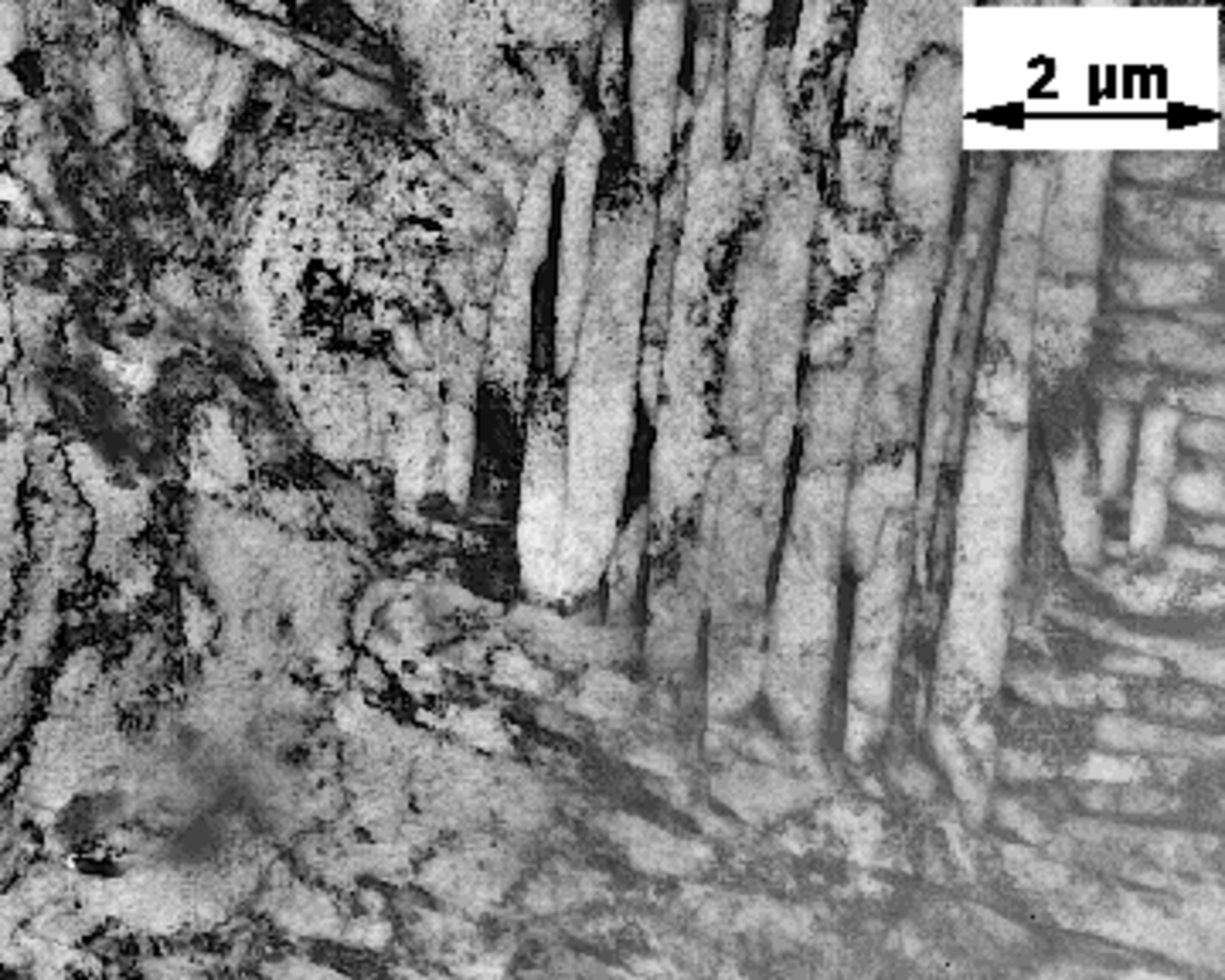

Harry - Well, most steels are crystalline in nature, so if you look at them in  a microscope, you'll find very fine crystals, usually of the order of a millionth of a metre in size. Now, the finer you make these crystals, the stronger the material becomes and also tougher. So, toughness is the ability of the material to absorb energy when you hit it, otherwise, the material is not safe when something impacts against it. So, the idea here was to make the crystals so incredibly fine that they're actually finer than carbon nanotubes. So that is talking about 10th of a billionth of a metre in size.

a microscope, you'll find very fine crystals, usually of the order of a millionth of a metre in size. Now, the finer you make these crystals, the stronger the material becomes and also tougher. So, toughness is the ability of the material to absorb energy when you hit it, otherwise, the material is not safe when something impacts against it. So, the idea here was to make the crystals so incredibly fine that they're actually finer than carbon nanotubes. So that is talking about 10th of a billionth of a metre in size.

Ben - And how do you actually do that? How do you go about controlling the size of these crystals?

Harry - We discovered that if we grow the crystals inside the solid steel at a low enough temperature then they will grow extremely fine. So in this case, we are heat-treating the steel at the same temperature at which you would cook pizza. The only catch is that we need to hold the steel at 200 ° C for 10 days. So it's a very long cooking process, at around 200° C.

Ben - And is it all about that heat treatment or are you adding extra alloying elements as well that give it these properties?

Harry - We have added silicon in particular to stop the growth of detrimental crystals. So, there are some crystals which are bad for toughness and one of those is iron carbide. And if you add the right amount of silicon then the formation of that ion carbide is suppressed.

Ben - So, we think of steel or at least I think of steel from a lay perspective is just being iron and carbon, but clearly, it is more complicated than that. How many different elements go into super bainite?

Harry - There's at least ten different solutes that we add. So apart from silicon, we add molybdenum because when we make the steel commercially, we can't control certain impurities, and molybdenum acts like a scavenger and gets those impurities, and therefore, stops them from doing harm to the steel. We've got chromium and manganese to stop other reactions which happen at high temperatures. So it's a very carefully designed steel.

Ben - Centuries of bucket chemistry have gone in to making better steels, but your technique has been somewhat more scientific?

Harry - Partly true. So what we do is we first start with calculations, go as far as we can, and then do the experiments to validate the calculations. If they're not correct, we go to that loop again. And that is a better way of doing it because we develop the theory at the same time as we reach our goal.

Ben - And speaking of the theory, what is it about having tiny crystals that gives it these properties? How does the crystal structure affect the final properties?

Harry - So, if we pack a very large number of crystals inside the same volume, then you are presenting a lot of boundaries between crystals to any deformation. And the finer you make the crystals, the greater the surface area between crystals in that given volume. So that makes it extremely difficult to deform. So super bainite for example has a strength in which one square metre would be able to support the weight of 2 ½ billion apples so that's what we call 2 ½ gigapascals of strength. And because the cooking process is so slow, we can make the steel in very large dimensions and very large quantities. So it's already been manufactured in thousands of tonnes.

Ben - We have spoken to people from Rolls Royce before on the show who have talked about how they make jet engine blades for example by actually just forming them from one single crystal. Now that obviously has none of these grain boundaries, but again, that performs a fantastic task for them inside the jet engine. Is it a trade-off therefore? Does having grain boundaries offer one thing and having no grain boundaries offer something else?

Harry - Grain boundaries are very good for obtaining strength at room temperature or let's say, 200 or 300° C. But as you go higher, about 500° C, there's a bit of space inside grain boundaries which is not inside the crystal. So atoms can move about very easily in the boundaries. What that means is that if you're operating a turbine blade at 1400° C, it gets longer and longer, so in that scenario, we really don't want any boundaries between crystals, and it's better to make the blade from a single crystal.

Ben - So, you have these incredibly small crystals that give you all of these huge surface area of boundary that gives you these unique phenomenal properties. How do you see super bainite really being deployed? Where do you think it's going to be most useful?

Harry - So I'll tell you both the good points and the bad points. The good points are that we can make this large in all three dimensions with an incredibly simple heat treatment. And the steel itself is quite cheap to make. There's nothing really expensive about it. So, in any application where we require a combination of strength and toughness, this is perfect. So for example for shafts, for armour and for bearings which Alan will talk about. The weakness is that because it is so strong, it cannot be welded. So, I could not make a bridge out of it for example. Large structures really need to be joined at some point, and this material cannot be welded at the moment. We are trying very hard to do research which will discover a method of joining it without disrupting the fine scale of the crystals. We haven't found it yet, but you know, this is science, right?

Ben - I get the impression from the little I do know about the way that we do join metals that actually there's at least another hour of discussion just in talking about how to join two pieces of metal together!

Harry - Absolutely.

Ben - Well, thank you ever so much, Harry. That's Professor Harry Bhadeshia from Cambridge University.

Comments

Add a comment